Our story

About us

The FRELION company, founded in 2006, has been an important manufacturer in the field of European production since its inception, focusing on the serial production of components for hydraulic hoses. Our portfolio includes a wide range of products that are characterized by high quality and reliability, which is confirmed by the fact that more than 95% of our production is exported to EU countries, where we have built long-term partner relationship

The goal

Through know-how developed over 18 years of history and repeated investments in technology and innovation, FRELION offers high-quality products that are competitive and able to meet the needs of an increasingly demanding market

Production facilities

In 2019, we moved and expanded our production capacities by moving to renovated premises in Vítkov in Moravia. This strategic decision allowed us to increase our production and deliver even faster and more efficiently. Our 3,040 m² production halls are equipped with the latest machining and automation technologies, allowing us to minimize human intervention and maximize production efficiency and the quality of our products

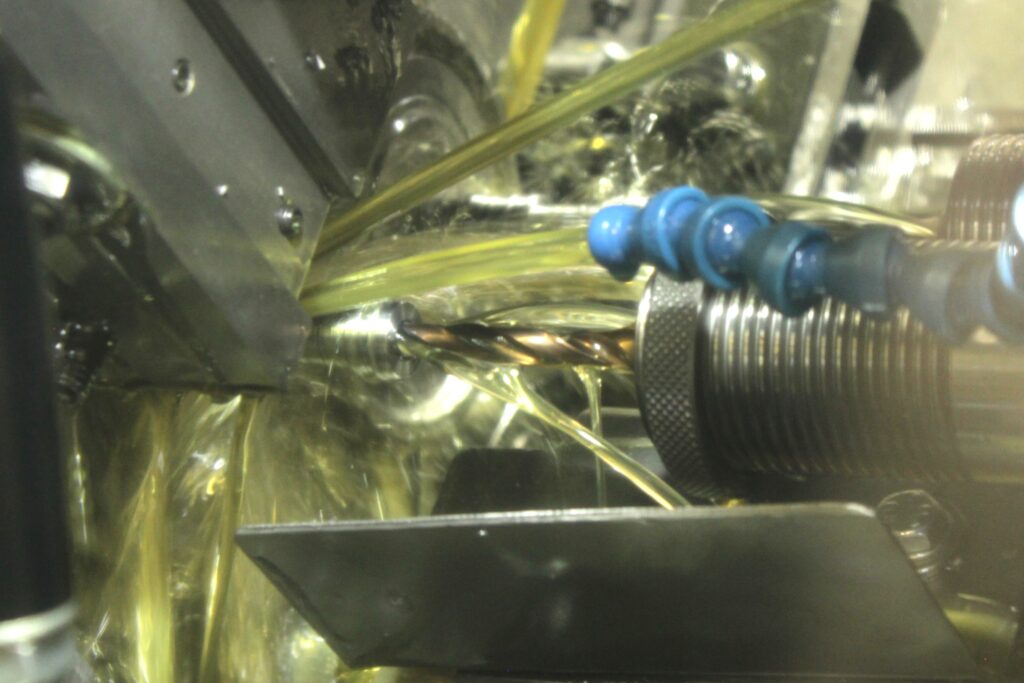

Technology

Our manufacturing capabilities include advanced machining on multi-spindle automatic lathes and CNC machines of renowned brands such as

TAJMAC-ZPS, TORNOS, WICKMAN BENNET, SCHÜTTE, EMCO, COLCHESTER, EMOTEK and others. We have more than 50 machines and devices, including EDM technology for the production of machining tools for our own production. Thanks to this technology, we are flexible and independent of subcontractors

Automation and robotization

Automation and robotization of production are key elements of our efficiency, while we use equipment and robots of brands IEMCA, PIETRO-CUCCHI, GIOVANNI-CUCCHI, KUKA, FANUC and others

Sustainable production

Our sustainable production also includes an automatic briquetting press, with which we process steel chips, the machining fluids can be used back in production, thereby minimizing waste and contributing to an ecological approach in engineering production

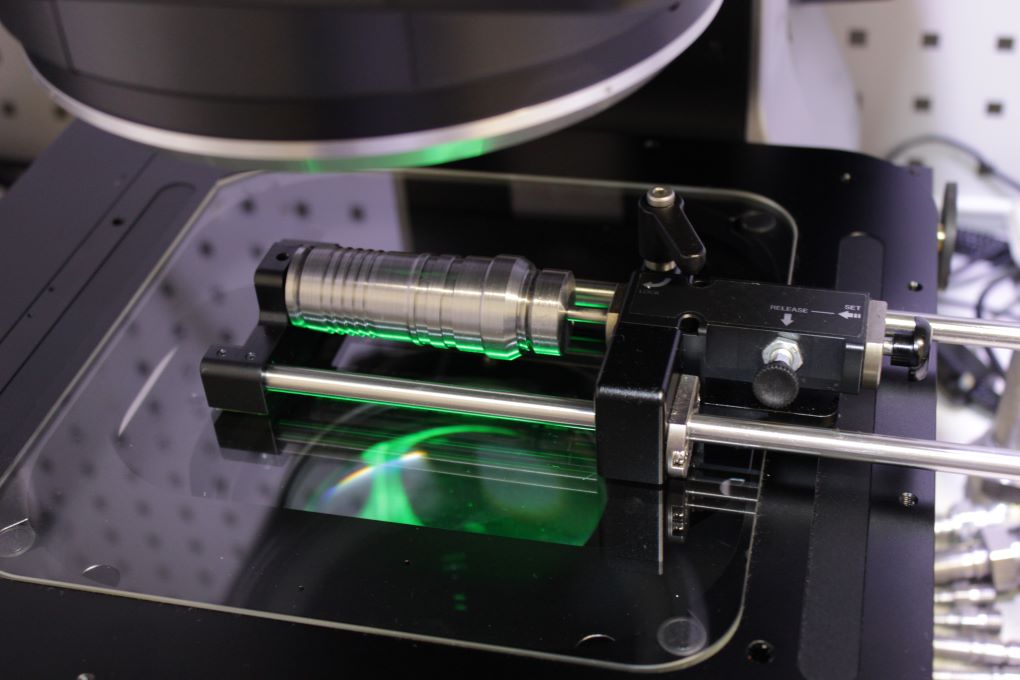

Quality

Our certification according to the EN ISO 9001:2016 standard is proof of our commitment to quality and continuous improvement. This certificate is a guarantee that our production and control processes meet the requirements of this standard.

Our quality control is ensured by automatic and semi-automatic measuring devices of the brands KEYENCE, SICK, MITUTOYO, INSIZE and others.

100% error detection is provided as per customer requirement using our own devices.